In February 2014, an international seminar “Prolog — an evaluation of log house construction related education and development opportunities in the Nordic-Baltic region” took place in Latvia, and later in Estonia. And here is what was said in the final resolution of this seminar. A call was made for log house builders’ trade skills to be included in United Nations Educational, Scientific and Cultural Organization’s (UNESCO) national world heritage lists.

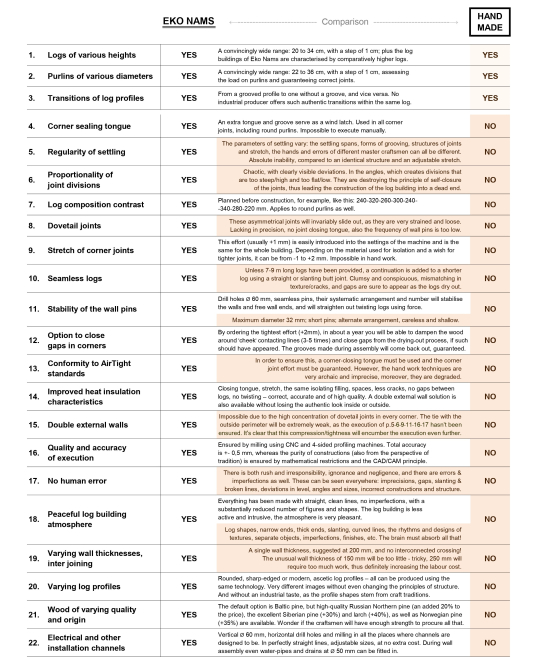

Interesting. You definitely want to know with what purpose, why such a concern? This invitation most definitely surprises you, but it is not surprising for us; we fully understand the seriousness of the situation or the condition. Perhaps you have already noticed how we are raising alarm in every way and trying to make you come back to your senses. Clearly, we agree, support and sincerely wish the association of enthusiasts at this seminar to complete the work planned.

Thus, after long discussions at this seminar, the reason for the association’s work or destination was conceived as follows:

To acquire some time to think, to take a step back. To organize one’s thoughts on what to do next with the issue of this trade craftsmen’s skills, and only then take the next step. There is no doubt that it is the responsibility of the specialists in the field to launch all conservational measures as soon as possible — to gather and preserve the valuable knowledge in order to be able to pass on this heritage to the future generations before it is too late! “

Along the lines of that. But does something not add up here? Did you not notice? But why do the participants of this seminar — true specialists, teachers, professionals of the industry, true log house experts and enthusiasts — ignore so many truly operating hand-work enterprises? That does not mean that the participants of the seminar do not know anything about the existence of this type of companies? But if they do know about them, do they really doubt and don’t they really recognize their mastery and professionalism? What is this? However, their explanation is quite simple and also completely logical:

All the so-called “hand-work” companies have been written off long ago and quite rightly so. It is obvious that there is no hope here, because it is very easy to conclude that these companies are no guardians of some valued traditions. It is clear that these companies will hardly want and will probably not be able to become the saviors of such traditions; moreover, they are hardly planning to get caught up in the restoration of craftsmanship traditions. It is with regret that we must ascertain the fact that the knowledge and potential of such companies is more than insufficient to fulfil the tasks listed above and that, in fact, the whole business orientation harms the craftsmanship industry and even distorts it in various ways. So, in the case of such companies, there is nothing to hope for, because money is almost the only measure of motivation and activity of such companies. In addition, a “set” of values of an ordinary or typical entrepreneur is rarely compatible with a higher level of ambition and ideas.

To illustrate thoughts – a typical image of pseudo crafts like that. A pile of logs, cold, semi-darkness and difficulties…

That is simply the way it is. And who would dare to not agree with such an assessment? Is there anything to object in this regard? We can only remark that the professional craft skills of such companies are also quite questionable, as well as their actual operations and experience, the knowledge they possess, their equipment, as well as these hand-held instruments. Yes, and certainly the finished product itself is also questionable. In principle, everything shows that there is nothing to inherit here, there never has been and never will be. It all sounds quite harsh, but these are indisputable facts.

Absolutely nothing coming from such companies can be taken to UNESCO’s national treasure storages.

It is clear that all of this is only the characterization of a modern business, it is clear that these companies do not have time for all sorts of sentimental nonsense, the romanticism of tradition, the brotherhood of craftsmanship and nostalgic, tear-jerking idylls. And let us not be naïve; people have to live from something, they have to eat something and not only they, let us not forget about sellers, intermediaries, marketing gurus, all of us. According to the opinion expressed at the Riga Log House Conference by Kārlis Apinis, head of the carpenter section of the Latvian Chamber of Crafts:

“But in this crazy competition there are also some advantages — a large number of carpenters who have the opportunity to prove their professional skills are participating in the construction of these structures, and often a professional from abroad is invited to provide a consultation, thus creating an opportunity to exchange experience. However, cheap carpenters from rural areas with high unemployment rates and cheap labor are most often used. These simple carpenters have a completely different view of the quality of work, which is far from meeting the standards of log house construction. Graduates of vocational schools are often recruited to build houses. It would not be bad if they worked under the guidance of experienced carpenters, but most often they are entrusted with building and managing the construction without supervision of a master of the trade. These newly-established firms do not join the Chamber of Crafts and do not try to certify their carpenters as fellows and craft masters of the carpenter trade. Often such builders leave the house to be after it has been handed over to the client and does not show any interest in its condition after that at all, which leads to various conflicts with the client and degrades the craft of log house builders’ skills and honesty, as well as the general image and reputation of log houses. The following very serious mistakes are made — trees damaged by bluing, mold and wood-borers are used for constructions; a poorly executed grooving or U groove and corner joints; poorly executed joist joints connected with walls; too small of a settling reserve in corner joints and also above windows, doors and vertical structures; no electrical wiring riser boreholes are made in logs; logs are not properly mortised with one another; and others.”

Facts will be facts, meaning that only a parody of the craftsmanship long gone remains. Masters of log houses themselves have a laugh about their represented industry on some forums, because they have noticed an extremely comedic fact long ago, namely:

Modern carpenters are not constructing log houses, but rather sawing them with chainsaws and angle grinders.

Then they also do not exclude that log houses that are made this way can be used to analyze errors one day, perhaps, to never allow such mistakes to happen again; they also philosophize on the fact that they will at least have somewhere to gather evidence from about this dark period of “craftsmanship” for some encyclopedia, and so on.

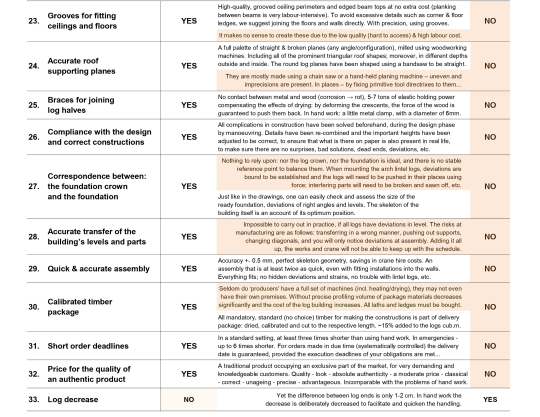

For comparison, a photo from the production plant of EKO NAMS LLC. Control assembly of the roof part of the log building.

Alright, but let us now get back to the case, back to the rest of the reasons guilty for causing the decline of this industry. It is clear that craftsmanship companies have been a part of a very fierce competition for at least a couple of decades already, and they have deliberately sacrificed a lot themselves just as they have been bound and forced to do it as well. It is crystal clear that without simplifying the product, without speeding up the process of its creation, without optimizing the techniques, it would never survive in this crazy competition. All of this is clear, but there are other very concerning doubts. The current level of competence of entrepreneurs and team managers in the industry, and their qualifications, to be more exact. Here are some of the most pressing questions:

- Have they started their business from the very foundations upon gaining knowledge?

- What is the origin of their knowledge and skills? What level of mastery do they have?

- Have they gone through years of apprenticeships?

- Have they achieved remarkable practical craftsmanship?

- Have they ever understood what is a simplified and hastened process of constructing log houses?

- Do they even know what deviations and mistakes are made at any given time, precisely in their “production”?

- Do they still make the mistakes upon knowing about them? And so on.

It should be noted that no literature practically exists. As of yet, no broad theoretical basis has been compiled with all the nuances, there are no drawings or related practical instructions. There are only superficial descriptions regulating disputes and standards currently in an embryonic stage.

Photos of the corner joints of so-called “log house” – contours of the “cheeks” are blurred, intersections of the “cheeks” are chaotic and do not meet at one point, central pin is too wide and appears even behind the contact line of the “cheeks”. Gaps between the logs and in the joints, and the edges of the central pin as a huge hole through which air can circulate freely. Maximum failure.

You cannot only fight with one another and participate in everyday struggles, because that way, step by step, the valuable craftsmanship skills will be forgotten, a lot of the unique knowledge will not be passed on. These worrying tendencies are not only evident in the log house industry. To add to that, it must be concluded with concern that many generations of businesses have changed over time under the conditions of such turbulence, but the fate of craft masters, once associated with them, has become unclear. And it is only logical that this is deeply concerning. The fate of the remaining craft masters is worrying, because they must necessarily be present in all companies, and these masters must carry out the training of workers in a knowledgeable and responsible manner. In other words, the question of how and of what quality the storage and passing on the of knowledge of craftsmanship is organized is clouded in a shroud of mystery, and one must simply trust that these modern entrepreneurs have not left everything go its own way long ago. Naively hoping that the construction workers will somehow deal with everything on their own.

By the way, it is unlikely that many of the workers or the so-called “carpenters” would even read all the instructions and special literature even if it existed. From our bitter experience, most construction workers today are too lazy, and they certainly do not want to stress about anything or think about things too much. In their opinion, the following “solution” is much more convenient — some craft master, one of their supervisors is always eager to explain everything to them, ready to provide them with all the answers, and in critical situations this individual makes the decision. And only he determines what and how to do, and only he bears all the responsibility for everything. The vast majority of workers do not even want to think and get involved, they are so hopeless, so uninterested. But perhaps it is only our opinion.

However, if they can’t cut even squared rafters correctly and precisely, as in this collage, then what else can you think of them…

Of course, the supervisors of such a construction workers are already more diligent and hardworking, and perhaps they are more qualified, but these supervisors cannot physically stand next to every single person in apathy or depression due to their life conditions. In any case, it is practically impossible to control everyone and everything. Moreover, the knowledge, skills, and abilities of modern superintendents are far below the skills of our ancestors. So, either the directors of these companies are unaware of the gravity of the situation or they can do nothing objectively, perhaps they do not understand or do not wish to understand. Alright, so we will point you all in the right direction.

Namely, the fact that it is necessary to find craft masters of a higher skill, or rather, create them on their own. From nothing. Sort out everything by yourselves and do not ask questions on where and how. In other words, it is vital for you to shape craft masters who single-handedly and with great pleasure are able to embrace the responsibilities of a knowledge bearer, trainer, implementer, maintainer, developer, organizer and rationalizer, as well as other responsible tasks. That’s why we have this concern, that is why we have this uncertainty about the existence of such remaining unique masters and the fate of craftsmanship schools. Someone is going to say that the concern is exaggerated… Alright, then, but what or who is the foundation, core, heart and spine of your craftsmanship company? Call him whatever you like. Does such a person currently exist? Is there even such a person?

Most probably, there is not, and the construction workers, both individually and collectively, are trying to speed up the log house construction process as much as possible, and they rush, thus ignoring minor and serious imperfections. Then, they, of course, are also watching one another and, unfortunately, starting to make the same mistakes. An obvious and easily verifiable fact — most log houses, the constructors of which are pursuing money and going for pace, are constructed without the necessary precision and care, without the right work attitude and, very often, also without any sort of thought put into them, without knowledge and experience, without the supervision of craft masters. Unfortunately, these facts are not only obvious, they are literally the first thing you see, and the results of such work cannot and will not be hidden by flailing their ISO and UKAS certificates, as well as other papers around.

As you can see, even the tops of the aisles cannot be precisely cut by these craftsmen. It is an endless threat, they damage so painfully, and so much… In completely unexpected places, in completely impossible ways.

For your information, in many so-called companies of poor countries the total budget of each order must be distributed between the workers by themselves. Yes, yes, even so… And then, watch them go, watch how much each of the workers will be able to seize from this project. And people do get greedy, they tear at each other to get as much as possible for themselves, their family and children and to repay their loans. In the name of survival, from the budget allocated to them, from the budget minimized to the fullest. Unfortunately, practically any work will be rushed in the constraints of similar payment systems or in such a stressful atmosphere, and the results will never be qualitative. Unfortunately, due to this reason “craftsmanship” companies will never be able to offer something that resembles the old traditions, quality and appearance of hand-work. And what kind of hand-work, what kind of aura can we even talk about there? If this is the response of companies (it is only a single example) in spite of competition and the pressure of price, then it is simply sad and pathetic, hopeless, even. Including the so-called “optimization” of taxes which is quite often used in these companies, it can also be called fraud of labor and other taxes… In other words, these are the completely wrong responses, completely hopeless directions, dead end of principle.

The result of this hopeless struggle – endless problems, in the concrete pictures – with the joints of the roof purlins.

All right, now let us theorize a little bit about this expressively emotional attachment to the stereotypes about hand-work. Or about your fantasies in the context of a special aura, and about placing such a log house constructed by hand or with a saw among something exclusive. I apologize for our skepticism, but does it not seem like sentimental nonsense to you? Do you really think that nowadays the construction of log houses is still taking place with true joy or love for work? Perhaps even joined by the singing of the workers? Or in a way that the log is examined first, going over the compatibility of different types of trees, and then gently and precisely created, caressed and declared as being good enough? Or with the craft masters nervously fidgeting, not being able to wait for the next workday? To be able to rush to work again to continue working with the little logs.

A thinking customer, who has sobered up from being overwhelmed by emotion, will soon snap out of it, realizing that today’s rush and day-to-day stress, tariffs, pace, deadlines, faults, risks, responsibility, competition, taxes and all kinds of uncertainty, definitely do not endow these houses with anything special or nice. Forgive us, but these narratives about the special aura are too far-fetched, because your log house will sooner have absorbed diametrically opposite emotions upon so many people tiring themselves out (so unprofessionally and heavily) to simply make a living. To be able to pay their bills! And, actually, how many of us can sense these metaphysical things? And would anyone really want to sense these layers of energy belonging to people who are strangers to you?

But, in truth, it is simply that only trees built into the log house’s walls are able to delight, warm up a person and help them recharge, that only they also truly give out a pleasant aroma, that only they create a very special and healthy atmosphere. Of course, if the owner of the building does not really notice various hand-work defects. Yes, it is undeniable that in addition to trees, a positive aura can be added to, both, a log house and any other type of building. But only as a result of careful and unhurried work, only by making it for yourself, wholeheartedly, thinking of every detail and falling in love with every single wall. Only that way. And so, it is the aura of a single person or a single family, and it is completely clear that you can add the positive emotions yourselves by elegantly setting up and decorating the log house, simply living and enjoying life.

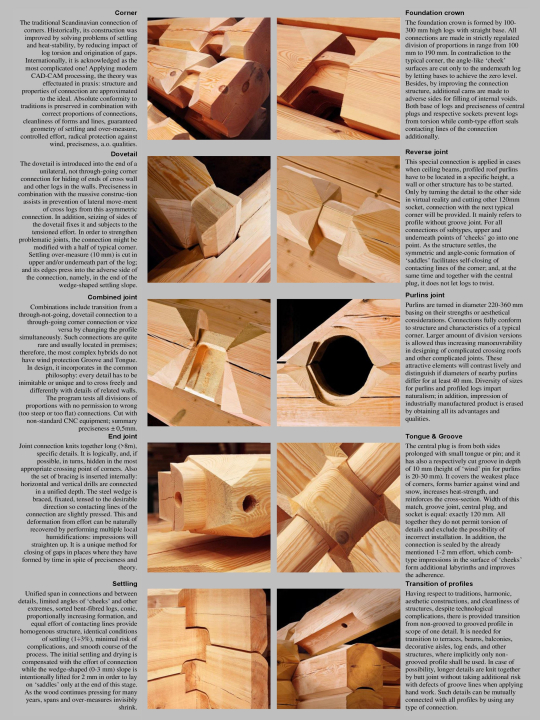

A photo describing EKO NAMS log houses – a natural, easily visible variety of log heights.

And again, a not very welcome surprise, a novelty or nuance. The message of this deviation again is dedicated to you, dear fans of hand-work. So, in almost all companies which so proudly call themselves log house professionals (even a more shameless characterization can be seen: “jewelers”), which loudly declare that they specialize in Norwegian log houses; yes, it is precisely these companies who specifically destroy the natural decrease and natural shapes of logs. That is, beams are specifically equated so that the difference in size between the thin and thick ends of beams does not exceed 1-2 cm. What is more, the shape of the beam is profiled with coarse, cheap electric planes, because then, you see, the company’s management does not worry when workers regularly break them. Meaning that a natural beam profile is not achieved, but rather a botched and muffed profile without using “those spokeshaves”, as to say, like our ancestors did. Whereas, in seemingly well-to-do companies, logs are proudly profiled with one-sided but very primitive equipment. This is how completely symmetrical, distinctly industrial but absolutely imprecise forms are “proudly” made, regardless of how modern, developed and well-equipped woodworking is, even regardless of the fact that it only acknowledges four-sided profiling machines. Yes, all of these so-called “log house craftsmen” have mastered the fact that it is not permissible to twist one’s “profile” or to twist one’s reputation by praising themselves and wooing the customer. Then you have to go all in and bluff without any hesitation and without losing a single piece of your confidence.

In any case, the purpose of the described handling operation is to eliminate most of the log-shaped diversities since they supposedly complicate and delay the work, since they supposedly substantially tangle up the combinations of future joint heights. Because it threatens to form too steep and too gently sloping joints, plus, it is already threatening repeated changing of some logs. But that is not enough, those shapes are literally pushing one towards a grave, that is, in constructive dead ends and situations that are difficult to resolve or are unsolvable; apparently they complicate the precise achievement of the basic dimensions of the house, they always make one use one’s head and calculate things, they make one predict in a timely manner and coordinate actions with other craft masters, they force one to keep looking for the right log for too long and to struggle for so long when copying shapes and while creating grooves. Those damned natural shapes… And what can we say at the end of this deviation or message, what can we conclude? Simply a great rationalization — to eliminate decreasing and natural, decorative forms. Or like this — how creative and professional, how innovative.

And here are the consequences of all this haste and ineptitude – heat leaks, condensation, mold, etc.

So, for some craft masters or companies — a lack of mastery, for some — lack of knowledge, for another — a deep backwardness. And if it is possible to notice all kinds of mistakes in almost every actually inspected hand-constructed log house, one is overtaken by the feeling that all craftsmanship companies, without exception, are exposed to the effects of a lack of knowledge and a threat to quality. We understand that this gloomy conclusion does not improve the reputation of log houses and the overall scene of craftsmanship, but what else should one think and what else should one do if the degradation process has advanced so hopelessly far, if gross errors and inappropriate methods are now openly demonstrated on the internet. Then, in our opinion, it is simply not enough that an industry expert mutters something under his breath or concludes something to himself, then it is necessary to change something, to do something about it. First of all, it is necessary that you, dear customers, also find out as much as possible about your beloved log houses. And any type of information, whether good or bad.

It really is not normal if such degrading “promotional” videos are being placed on the internet. They should definitely have been buried underground, deleted or burned. But no, it turns out that companies are still trying to boast, swash and even promote themselves by using these. Probably their creators have never thought about the structure of log houses, their nature and qualities or about their damaging and superficial actions and inaction, and they probably do not even realize in which episodes they show any errors. We will not mention the names of these companies, nor the links to their videos; let us just say that they are foreign hand-work companies, which are quite well-known in Norway. By the way, many of these companies are also not shy to attract customers with exaggeratedly low prices. It is a desperate step but if you present yourself as some kind of saviors and well-doers, like those who have perfectly organized their production that they are able to offer this exclusive product for an extremely low price. And if they are full-heartedly making sure that anyone (someone gullible) can get their dream house… It looks like many people believe them; oh, the enchanting and “fantastic” marketing. But in our opinion, for these fools log houses are simply a source of profit and satisfying their ambitions, and these videos are very cheap and, in their opinion, also a clever marketing move, just another move. You can be sure that upon seeing the films made by these amateurs, the old craft masters would turn around in their graves several times.

Even such a simple shape as the ceiling line these “masters” cannot cut straight and accurately. Only “pig” diggings, such are the consequences of this haste and attitude.

Yes, and something else to continue the topic of these websites – company signboards and advertisements. Most companies love to hang up all sorts of dubious awards gifted by simply profit-oriented state and non-governmental institutions on their websites, as well as annual export awards. For an additional illusion of seriousness, it is, of course, also recommended to decorate these websites with all the possible logos of the EU and other sponsors of their projects. Of course, links to all social networks must also be placed on there and then, of course, these social network accounts must be filled with enthusiastic plots of the seeming hyperactivity of these companies. Of course, the unverifiable existence of the FSC, ISO and UKAS certificates mentioned above and other basically purchasable certificates must also be evidenced, their involvement in all kinds of serious societies and grand projects (only in terms of its name), participation in intelligent seminars and other things must also be accented. And why not try to attribute innovative-like activities to oneself, why not create an image of an innovative company? It is so easy! For example, take part in one of the events organized by Innovasjon Norge, just like that — for nothing, simply as viewers, and then shove it into everyone’s faces at every possibility.

But, it would have been better to pay attention to the quality of the logs used – to rot, to growths, blueness, woodworm passages and other faults.

However, it still resembles a stuffed turkey. Only in this case, the “turkey” is pomposity filled with empty air. Does it not reveal the insecurity of these companies by showing such “convincing” arguments? Where is even a single word, in its essence, about the product itself? Does that not seem suspicious to you? And then this, a name so popular today — innovation. In case of hand-work? Funny, it is. Is it all an attempt to conceal the truth, to cover up one’s backwardness? Perhaps, to hide one’s jealousy? One can only hope that many customers are concerned about this regalia and exaggerated phrases showcased on these websites. It is all too sweet, so many attributes, many loud words and some kind of sickening movement. Bad feelings have to start to appear, whether you wish for them or not. Because which buyer does not know that they will not be dealing with internationally recognized companies and brands? Yes, the price is relatively low, but will the rest go even half as smooth as these companies are trying to tell you?

Will all splintered, rotten and split logs be separated? Will all defects in the wood structure be evaluated?

It seems that in relation to the subject of websites, we must, however, also include some harsher realizations and truths. For example, the fact that these companies must say on their websites and everywhere else that they are not safeguarding traditions, but rather are engaged in simplifying hand-work handling techniques, operations and shapes. So, in fact or in essence — in the degradation of quality and tradition, and for a very long time at that, for at least the last 25 years. And they should try to convince all log house enthusiasts not of the fact that they could do it but simply do not wish to invest in all sorts of equipment (due to the fact that they bravely stand watch for hand-work traditions), but truthfully admit the fact that they do not have the slightest hope of carrying out these complex technological activities, that they neither possess the courage, nor the passion to even dare to do something of the sort. And that they have no sign of any enthusiasm lying deep down, that they only have the desire for profit, an empty arrogance and a longing for ever-increasing turnover. Finally, it would also be advisable to truthfully admit that, in fact, their only weapons are these — a shameless and aggressive marketing, plus the dumping of prices at the expense of dogging their workers around. Unfortunately, because these are the “weapons” that contribute to the decline of tradition and quality.

In the photos – flooded foundations as a serious problem of the builder’s attitude. The logs intensively absorb moisture and the log house becomes moldy and blue, possible wood rot.

On the other hand, the companies that did not have such ammunition in their arsenal or it was not their practiced style have long been forced to stop operating in the craftsmanship industry; this also includes a very large number of well-known Norwegian hand-work companies. Quite an unfair and even an absurd situation. But is the business of such pseudo lucky people and of these survivors not already hanging by a thread? Will it continue to be possible to simply get away with empty promises and self-praise? Will it be possible to continue this boasting, will it be possible to manipulate the customers by deceiving them and mentioning traditions and the so-called hand-work whenever necessary, will it continue to be so simple?

Will it still be possible to continue bypassing and ignoring the most important factor — the quality factor of the product?

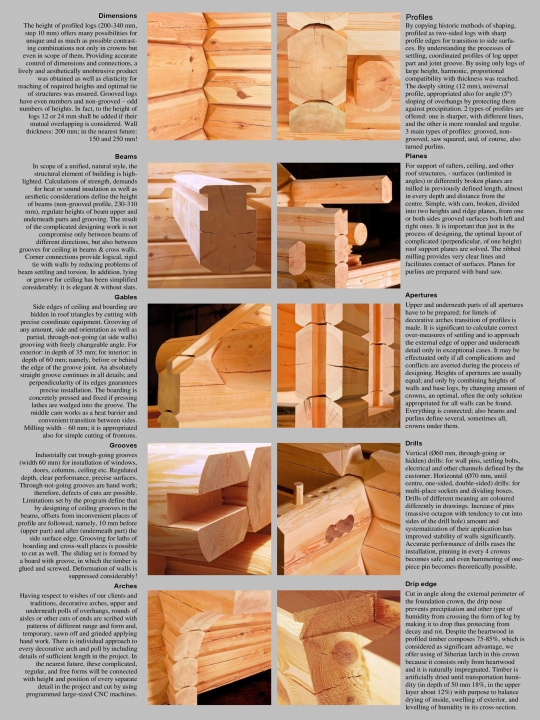

A photo that is a pleasure to look at. Our corner joints in a log house made from Siberian larch.

The wisdom of the people tells us that “a fish rots from the head down”, and indeed, the signs of rot can be found not too far away. Namely, Robert W. Chambers from the USA, who is the President of the International Log Builders’ Association and the most active and titled participant at the Riga Log House Conference mentioned above, expressed the following opinion already back in 2005:

“Modernization processes in log house construction are inevitable,” calling himself and the other participants of the conference log house “orphans”. He, and not without envy, emphasized that “construction of log houses using chainsaws, cranes and scribers, unfortunately, does not correspond to the concept of something modern if we compare how highly developed woodworking is in general, how fantastically advanced woodworking methods and tools are.” Then he nostalgically remembered that in 1993, when he first visited Latvia, only axes and spokeshaves were used to make joints and U grooves and that he even heard the craft masters sing. But then, upon, perhaps, finally snapping out of this dreaming while being awake, quite unexpectedly Robert W. Chambers himself begins to offer very economically profitable “hand-work” innovations — innovations patented by the man himself. In our opinion, the complete nonsense, for example:

- OLAT (One log at a time), method of marking and adjustment. The essence of “innovation” is to mark all logs at the same time;

- ALB (Accelerated log building) the emphasis is put on increasing the pace of creating a grooving, which is not less than 20 minutes per meter, when the craft master has already gotten himself used to the work. Tested on about 200 projects;

- CIY (Cut it Yourself) Although the title of this “innovation” reminds us of the mocking of the client, it is a new product or invention in the best traditions of semi-manufactured goods, intended for customers who like to some of the work themselves;

- He also promises to present the new generation of ALB (Accelerated log building) in which the masters mark the corner joints and directs the logs to the sawmilling points with chainsaws. And then perhaps it will be possible to package all the details right there on the spot, right away. Perhaps…

At the end of the conference, Robert W. Chambers does not stop fantasizing and does not settle down, even dreaming of fully automated lines and methods. In the end, however, he mercifully comforts the participants of the conference by including a promise here and a hope there:

I bet there will still be a small share of the market for exclusive, fully hand-constructed log houses. But only for those which have not been touched by chainsaws and other brutal mechanical tools.”

Please excuse us, but if these delirious ideas and “innovations” are put forward by the president of the International Log Builders Association, then it really resembles a collapse. Alright, God be with all these associations. We will simply also underline the causes of this whole log house ruckus, once again reminding you that mastery is mainly degraded by the constraints of pricing and costs and the pressure associated with it, one that is also coming from the end-buyer. And we end up with somewhat of a vicious cycle meaning that the fee for the low price is a low quality, disappointment and headaches for the customer. And it is only logical that the pressure of customers does not pay off at all if it comes back to haunt them. It seems that up until now the wish of the buyers for companies to ensure that high-quality log houses are produced at low and extremely low prices has remained unfulfilled and may remain as such. Perhaps it is precisely because of this exaggerated requirement and their own inadequate tactics – also curved walls, level deviations and displaced structural nodes.

But please, do not despair because, of course, any wish can be fulfilled, and this determinate statement is directly and confidently confirmed by the product which we have created. It possesses both, a high quality and a good price, however, in the case of such a complex type of log house (with Norwegian corner joints) that is a lot, even quite a lot to expect, and such a wish cannot be fulfilled within a day and even within a year. But above all, it can never be brought to life by continuing to operate with the same old methods and with various nightmarish improvements of techniques or with silly innovations. Simply put, in that case both, the quality of the product and its processing techniques will be gradually and irretrievably destroyed, or that is exactly what has happened in the field of today’s craftsmanship. And how could it be any different if even the price of such a house, which is seemingly adored so much and seemingly so exclusive, must be reduced, if pace has seemingly become the only salvation for the hand-work specialists?

Most often, the increase of pace is stimulated by companies themselves reducing the cost of hand-work — for the creation of corner joints, for a meter of grooving and sawing, and so on. Additionally, by systematizing each operation, pricing each activity and introducing new types of piecework, but, in any case, tightening the “belt” more and more. Managers of “craftsmanship” companies that have met some difficulties are forced to cut all these tariffs by evaluating economic and practical considerations, often juggling on the boundary of the survival of such companies and their construction workers. It is clear that this is the way things happen nowadays at any rate; unfortunately, it is impossible to expect or create significant rationalization proposals in the craftsmanship environment, it is not possible to introduce measures facilitating and compensating work.

So there is almost nothing that can be done to aid the victims of this tariffication, the workers whose hands are bound, as well as in regard to increasing the profits of businesses. Excuse us, there are some other options for profit, however… A thing that we mentioned earlier is being practiced, meaning the so-called “optimization” of labor and other taxes, including illegal employment, envelope wages, illegal double accounting, etc. And it is not some joke, and it is not funny at all. All right, but what do the craft masters have to do in all of this, and do they have any choice in it at all? Should they get involved in this madness, forget about the accumulation of their pension, start rushing everything even more? Maybe they should proudly lift their hat and starve?

Unfortunately, many “craft masters” are not going to lift their hat, they do not wish to live in starvation or even half of that, they still choose to take the road to degradation. Yes, it is possible that most of these people are or were forced to do so, no one is judging them. But whatever the case, their principal choice, too, moves the log house industry one step closer towards its crash, and this, in turn, irretrievably leads to speeding up and distortion of all possible work methods. Speeding up at the expense of quality and simplification of constructing structures and joints.

By the way, this trend is particularly applicable to all industrial manufacturers of log houses, even including the leaders of this segment from Finland. The leaders of the world. Such structures can be referred to as log houses only partially, and they can more precisely be characterized by such names as: calibrated log, beam, milled log or adhesive beam houses. The whole thing looks hollow and cheap, in fact, all that is there are piles of cheap logs.

So now, only the occasional craft master practices repeated or specified marking of corner joints and grooving lines. Now, in order to speed up this process, all sorts of tricks and unsuitable tools are being used instead, including marking levelers or the so-called scribers from Canada. By the way, they are only suitable for their giant-sized cedar logs. Now, employees tend to mark and create joints in a single go, and the handling process is rushed by using angle grinders and chainsaws. Now, a brutal and exaggeratedly deep forming of the log grooving shape is performed, now, the intersection of the “cheeks” of the joints almost never crosses at a single point, now, one joint has a higher tightness while another one has gaps in one or all of the contact lines. And which is more, uneven settling conditions, unequal gaps, incorrect, illogical and contradictory grooving forms are made in a hurry, and so on and so forth.

And it will not always be so that they will be able to afford to properly store and qualitatively dry wood, they will not always be able to afford to throw away unsuitable and moldy logs, and it is unlikely that they will be able to afford to get rid of all the logs that have a crooked wood-fiber, see pictures.

They will certainly not be able to do all of this due to the fact that they will not be able to afford it financially, because, after all, they are forced to sell their log house, constructed with great hardship (if the work has been completed with no rush), at a favorable price. In principle, the words survival and despair most accurately characterize things related to log houses and the true condition of hand-work Because, either running after profit or simply in the name of survival, these “true hand-work” companies can no longer afford to properly prepare the trees in winter, nor can they fantasize of cutting them down during the right phases of the moon.

Logs should be cut at the time when trees contain the least amount of water, meaning, from the second half of December until the end of February. Coniferous trees are cut during a growing moon phase starting from the third day after a new moon and ending with one day before the full moon. It is believed that the houses are long-standing, they conserve warmth, no wood-borers appear, and the logs crack less.

By the way, we are not doing that either, because in large-scale manufacturing it is practically impossible to do, nowhere in modern wood-working. In turn, in the real area of hand-work — no problem to do that, or, simply put, that is their field, they take pride in that. Yes, but then another essential question arises, one leading to serious contemplation. For these log houses that have been constructed with great difficulty. A question for you.

For whom exactly has their price been or will be beneficial?

Not for buyers or for sellers. Maybe nobody? Alright, then another question, for you again. Can you currently find at least one elite hand-work company in Norway? One who functions normally, who has a schedule full of log house orders for at least a year ahead? Yes, there was once a time when a company named Malmlaft AS was operating in Norway, there was once a time when in Latvia, under the umbrella of the Latvian Chamber of Crafts, log houses were constructed by true enthusiasts of the profession, unquestionable professionals. Was… Regrettably, many of these respected companies were swept away into nothingness by the global financial crisis of 2007. But, if we must be honest, the level of these companies and the price, however, was or will be available to very few customers only. For example, in Latvia, the services of such companies were only affordable to our president, the head of our gas supplying company and certain very wealthy entrepreneurs.

And what exactly should you conclude after having read the paragraph above? Simply the fact that constructing a log house is not to be taken lightly, and if the customer is not willing to pay the price for hand-work, which is well above the average price of the market, then he or she does not have much left to hope for. There are no miracles, and there is absolutely no reason to live in a fantasy — it is then better not to even begin such a project, it is better not to spoil this dream. It is more logical and incomparably wiser in such cases to build a log house from industrially manufactured logs, with a guarantee of quality and precision, for a sufficiently adequate and understandable price, knowing exactly what you can expect. To illustrate this thought, try to visualize, for example, the appearance of stairs, doors, a table or a chair made only by hand and with primitive tools. Try to realize the highest possible quality of such products, and then compare these ideas with the potential of modern industrial products. And definitely consider the systematic approach of manufacturers, the product guarantees, substitutability of components, consider their price and quality level correlation and so on.

Photo: EKO NAMS log house assembly in Idre Fjäll, Sweden.

Of course, we can continue to complain for a while longer but all of this must be addressed! In hopes that you will appreciate our efforts, trying to turn your attention to the rather sad situation in the log house industry so cruelly, with extreme measures and by using exposing methods, in hopes that maybe then hope will rear its head. In hopes that the situation can still be mended or saved, that customers will finally begin to think, that they will finally start demanding a stable quality level conforming to modern standards, that they will cease to ignore their own interests.

Photo: EKO NAMS control assembly of log buildings and additional works in Livani.

How strange this is, but customers often and for various reasons do not even receive information about other offers from the market and its players, about the product alternatives freely accessible to the customer and that also includes our product. Many builders are simply unaware of all this, some choose to remain silent, while others tend to distort the facts for the sake of selfish interests, which is even crazier. As a huge surprise, we recently found out that at last (meaning, only 20 years after our product entered the production phase) some very active construction companies have found out about our log houses for the first time. So, a question — how many more representatives of the industry are there who have not heard anything? And, to be fair, how many customers and people potentially interested in our log houses have heard anything about our product? Probably nobody? All right, so let us try to find out and explain why this has happened in one of the continuations of this blog.

Sincerely, Ervins Poga

By the way, in order for you not to think that someone is talking nonsense in these articles or, even worse, brainwashing you, we invite you to read the short two-page version of our brochure in the appendix. The brochure systematically, in essence, reveals all the nuances of our product, without missing any of the elements of log house structures which are valuable in regard to preserving tradition. Although this is how we lay out all our secrets in detail, we are not concerned at all about our future simply because we are not stagnant in our development. The path to implementing all of this in real life will be long and difficult enough for anyone.

By thoroughly studying all the small details of the construction of log joints described therein, you may come to the realization that the brochure can also be used as a handbook for any of our followers. At least, during the brochure creation process, everything was willingly revealed, with a relief that the matter had been resolved and that the product is in working order. In other words, nothing was hidden or concealed from you. Will the industry professionals acknowledge that our product is not necessarily an expression of some excessive nitpicking, but that it has been shaped in true respect for the wisdom and ancient traditions of our ancestors? We hope they do. Because by doing our best to preserve or even save these traditions, we also gave ourselves an additional task: to improve the quality of wood buildings, which can be characterized as quite specific, to create a harmonious, beautiful and finished product, to create a modern and lasting technology. And here comes the promised comparison table: